1.2 Stresses and damage in super alloys during thermal and mechanical cycling

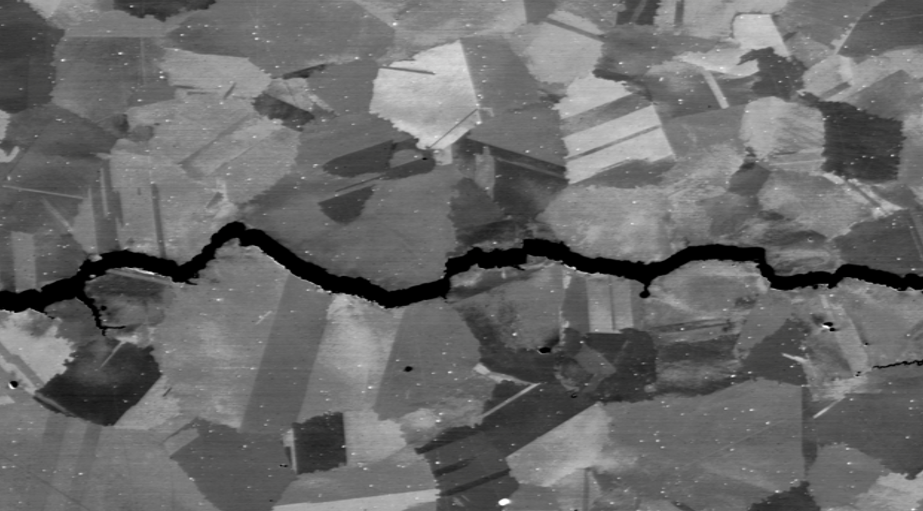

LSI experimental techniques will characterize superalloys' thermomechanical behaviour and damage development. Such experimental information will enable the development of new modelling tools for predicting microstructures and, in particular, for grain boundary engineering.

This is especially important when the microstructure variation coincides with a complex component geometry.

Project summary

Superalloys are an important class of materials in the transition to make gas turbines for aviation and power generation more sustainable for the future. These materials are often indispensable for components to operate under extreme conditions with respect to temperature, load and aggressive environments. At the same time, they must ensure safety, reliability, efficiency, and durability. The focus of this project is on experimental characterization and modelling of the thermomechanical behaviour and damage development for superalloys supported by the utilization of LSI. Special focus will be on developing tools that can predict the properties of superalloys with complex or tailored grain structure. The goal is also to develop methods for grain boundary engineering of high-performance superalloys.

By combining the unique opportunities provided by the LSIs with a physical based modelling framework it will be possible to develop tools for describing and predicting the influence of microstructure on the properties of superalloys. This is important for applications with complex or tailored grain structure, especially if the microstructure variation coincides with a complex component geometry when it can be almost impossible to test the mechanical performance of the material using standard test methods directly and experimentally.

Project duration

2024 - 2028

Key project participants

Project Lead: Johan Moverare (Linköping University)

Project partners

Linköping University, Chalmers University of Technology, Siemens Energy, GKN Aerospace