2.2 Microstructure and damage evolution in hydrogen environments

LSI experiments for studying hydrogen degeneration will be used to improve computational tools - for predicting the hydrogen resistance of new material designs

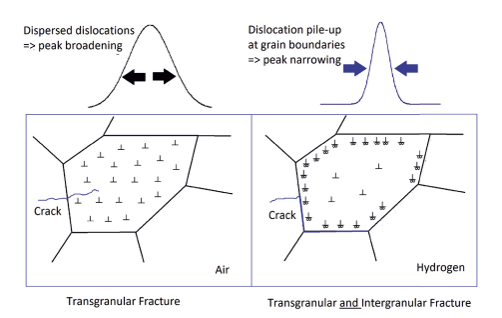

Project summary

This project will review the needs and possibilities for performing LSI experiments to study the hydrogen degradation phenomena of steel and how data from such experiments can support the development of computational tools for predicting the hydrogen resistance of materials. This can for example include detecting trapped hydrogen in the microstructure, or bulk solubilities, ex-situ in pre-charged specimens and later relate to behaviour during in-situ external loading. For the computational tools, it is of high interest to improve thermodynamic databases to better include the hydrogen-metal interactions.

The project gathers a wide consortium of material producers and the manufacturing industry with an interest in understanding how to implement materials in hydrogen environments, e.g. gas driven engines, bearings or various types of structural components like tanks or pipes. The project will include a literature review on the current state of the art and available sample environments to be used for a better understanding of what will be needed to study the different vases defined in the project.

The project will include an initial experiment to try to measure hydrogen after ex-situ experiment. The gathered will define how to move forward in the different cases in a continuation project, possibly with external funding applications, for either performing experiments in existing suitable sample environments or designing and implementing a new environment to meet the needed conditions.

Project duration

2024 - 2025

Key people

Project Leader: Niklas Holländer Pettersson (Swerim)

Project Partners

Swerim, Outokumpu, Ovako, Scania, Siemens Energy, ThermoCalc