2.1 In-situ corrosion investigation of the metallic alloys

Developing methodologies for in-situ corrosion investigation - for the development of corrosion-resistant alloys

Project summary

This project aims to explore how synchrotron- and laboratory-based in-situ measurements can provide complementary insights into the role of alloying and trace elements in the corrosion performance of aluminium and ferritic alloys. A key focus is the development and refinement of methodologies for in-situ corrosion investigations, which hold the potential for advancing corrosion-resistant alloy design.

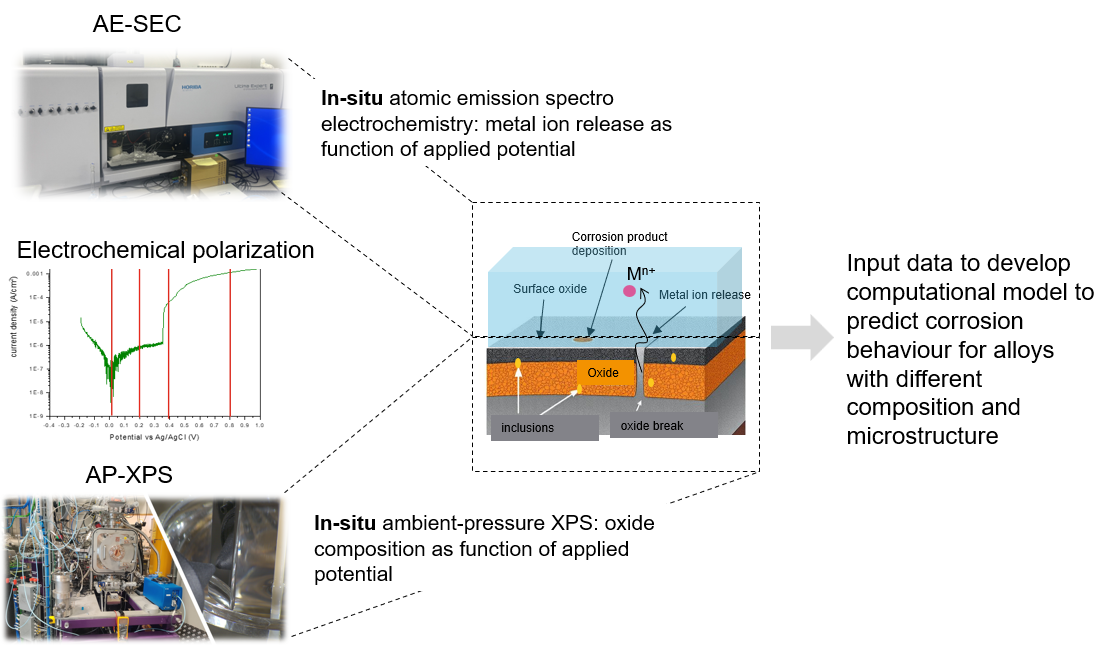

The approach integrates in-situ synchrotron-based ambient pressure X-ray photoelectron spectroscopy (AP-XPS) with in-situ laboratory-based atomic emission spectroelectrochemistry (AESEC). AP-XPS enables real-time tracking of oxide composition evolution as a function of applied potential, whereas AESEC provides quantitative data on the type and concentration of dissolved elements released into the electrolyte. Experimental results from these techniques will be complemented by structural investigations and computational modelling in order to enhance predictive capabilities.

By combining several techniques, this project aims to establish a robust framework for understanding corrosion mechanisms at a fundamental level. The data generated will contribute to the validation of predictive models for corrosion resistance, enabling the design of alloys with optimized composition and microstructure for enhanced durability in corrosive environments.

Project duration

2024 - 2025

Key people

Project Leader: Konstantin Simonov (SWERIM)

Project partners

SWERIM, Ovako, RISE, Scania, Thermocalc