3.1 Solidification and phase transformation control for sustainable manufacturing

Assessing the dynamics of materials' behaviors during manufacturing processes, particularly focusing on melting and solidification in additive manufacturing (AM) and casting of recycled metals.

Project summary

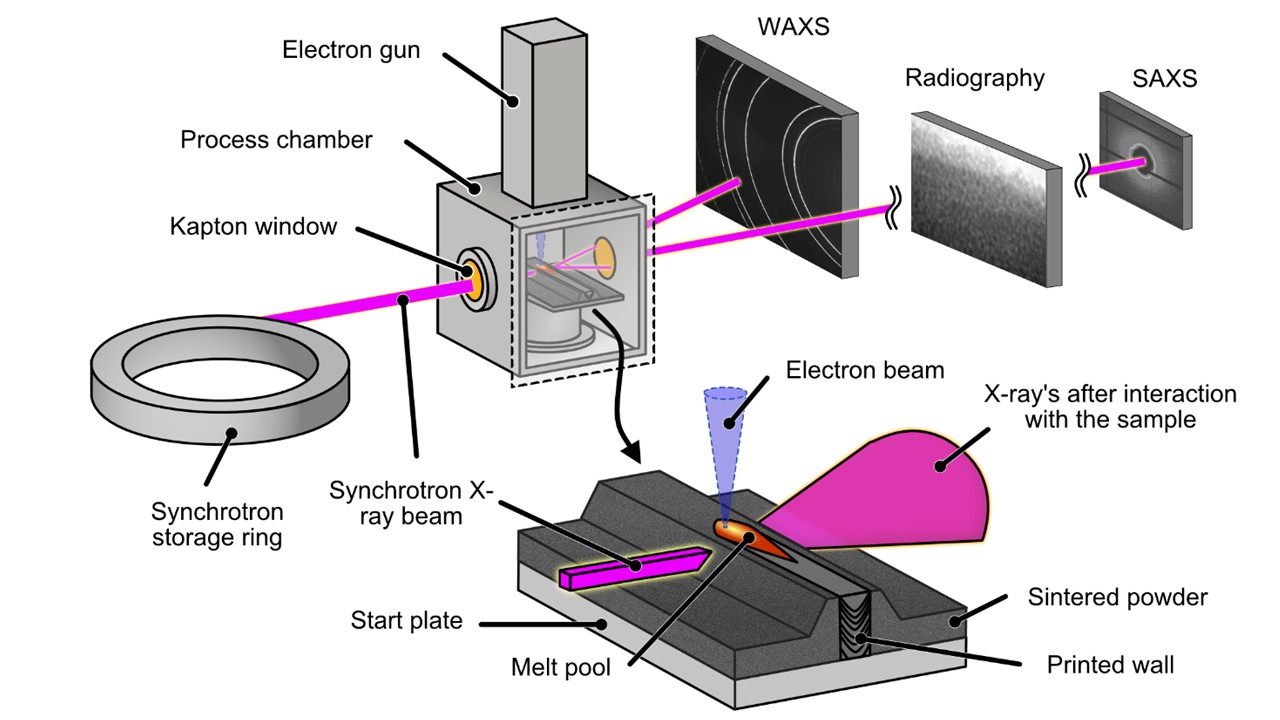

This research aims to enhance the understanding of materials' behavior during manufacturing processes, particularly focusing on melting and solidification in additive manufacturing (AM) and casting of recycled metals. Utilizing in situ/operando observations and large-scale infrastructure techniques, the project focuses on the complex mechanisms governing the microstructure evolution in real-time manufacturing conditions. By using a dedicated sample environment and employing high-speed X-ray imaging and diffraction/scattering measurements, the project aims to investigate melt pool dynamics, phase transformations, and nucleation and growth phenomena.

The goal of the project is further to develop methodologies for integrating in situ data into modeling tools, facilitating the validation and optimization of process and microstructure models. Through collaboration with industrial partners, the research aims to contribute to the development of sustainable materials and processes, with a focus on utilizing secondary metals, reducing machining costs, and enhancing tool performance.

The project is structured into four work packages dedicated to in situ experiments, data analysis and modeling, materials/process development for AM, and casting of recycled aluminum alloys. By bridging experimental observations with computational modeling, this research will provide valuable insights and tools for the manufacturing industry to drive innovation and sustainability.

Project duration

2024-2028

Project lead

Greta Lindwall (KTH)

Project partners

KTH, Freemelt, VBN Components, Scania, GKN, RISE, LiU, Thermo-Calc